Cogeneration/CHP

Cogeneration or CHP (Combined Heat and Power) solutions from INNIO are designed to generate both heat and power increasing overall power plant efficiency up to 90% and even more.

INNIO's Jenbacher CHP systems use the waste heat created during an engine’s operation to generate overall CHP plant efficiencies of more than 90%. This efficient and economical method of energy conversion achieves primary energy savings of roughly 40% by using a gas engine cogeneration system instead of separate power and heat generation equipment. Transportation and distribution losses also are reduced or eliminated as the decentralized energy supply is aligned where it is needed.

*Based on IEA ’16 electricity production figures for EU-28 and EIA ‘17 average power plant heat rate references

INNIO Cogeneration solutions are used by our customers across the globe, powering applications in variety of economy segments, for example - industrial manufacturing, commercial, municipal applications, greenhouses and many more.

Jenbacher onsite cogeneration solutions can help our customers to achieve economic targets thanks to one or several of factors, such as:

- Decrease of Energy-related OPEX compared to centralized energy sources, or

- Launch/extend company's operations due to new power access in energy-deficit areas, or

- Minimize downtime thanks to improved quality of the electricity supply in regions with unstable grid infrastructure, any much more

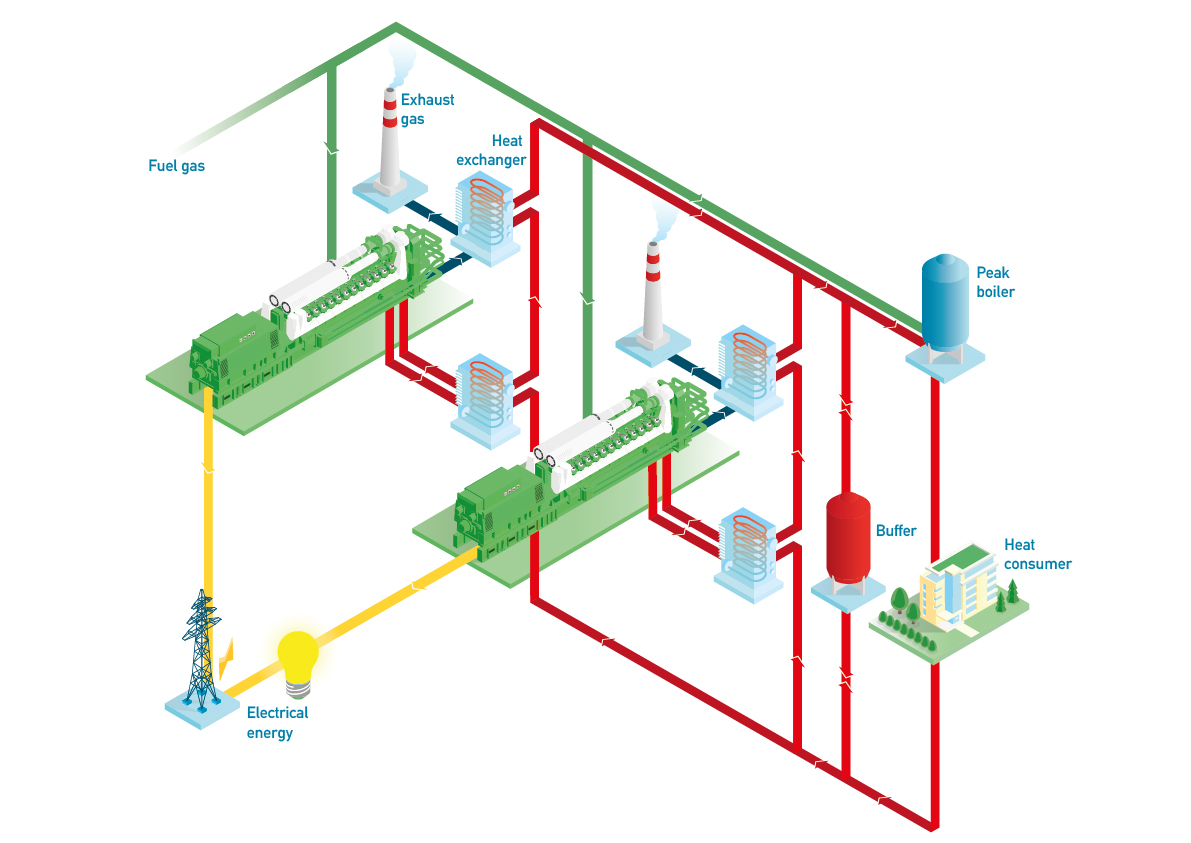

The basic structure of INNIO's Jenbacher CHP systems includes a gas engine/gas generator unit and heat exchangers that use waste heat. A wide range of heat sources—from gas engine cooling water and oil to an air/fuel gas mixture and exhaust gas—is configured to give each individual customer the greatest possible benefit. Our cogeneration plant solutions deliver flexible power generation and a high degree of reliability and availability.

Jenbacher CHP modules can be installed inside buildings or packaged into ready-to-use containerized CHP solutions. Containerized cogeneration power plants allow our customers to start using the benefits of onsite power generation quickly.

OUR EXPERTS ARE READY TO HELP YOU

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, INNIO´s regional experts can advise you on which solution makes the most sense for you.

Get in touch for free consultation on the following:

- The benefits of onsite power generation solutions for your company

- Potential financial benefits using economic modeling

- Consultation on the technical side of your project - fuel types, feasibility studies, equipment and balance of plant selection, and more

- Regional incentive programs relevant to your business

- Options to deliver your project: purchasing, financing and leasing, engaging a service provider (ESCO, BOO etc.)

- How to meet emissions targets

Fill-in contact form, or send us an email contact.en@innio.com

Spotlight on CHP solutions for Healthcare:

INNIO Barts NHS Hospital:

INNIO Kings Cross Hospital:

Cogeneration systems can be supplemented with a boiler system for bridging peak heat demand periods. The connection of a heat storage medium makes it possible to increase system operating time and efficiency.

Cogeneration power plant electrical switch and control systems distribute electricity and manage the engine, while hydraulic equipment ensures heat distribution. Generated power is used by a facility or fed into the public power grid.

The thermal energy can be used to generate heating water and steam production as well as for various types of process heat.

Gas engine cogeneration systems also are used for CO2 fertilization in greenhouses and trigeneration systems (combined generation of heat, cooling and power).

Features & Benefits

- Cogeneration systems generate both heat and power.

- INNIO’s cogeneration gas gensets are designed to maximize electrical and overall efficiency: yielding 48% electrical efficiency and combined heat and power efficiency up to 90%.

- Generally, 40% more energy is saved vs. separate power and heat generation equipment.

- An approximate 18% boost in exhaust energy is available.

- Cogeneration reduces or eliminates transportation and distribution losses.

- Operating time and efficiency are increased further by adding a boiler system or other heat storage medium.

- Full power is achieved within 10 minutes.

- Generated power is used by an individual facility or fed into a public power grid.

- Thermal energy can be used to generate heating water and steam production, as well as for various types of process heat.

- Designs are lightweight, compact and modular.

- Application is suitable for CO2 fertilization in greenhouses and trigeneration systems.

'Q & A 게시판' 카테고리의 다른 글

| Help:IPA/Hebrew (0) | 2022.04.21 |

|---|---|

| Perseus (0) | 2022.02.19 |

| what is Hmolpedia? (0) | 2022.02.17 |

| 일지작성 엑셀양식 (0) | 2021.10.04 |

| 페르마의 마지막 정리란 무엇인가? (0) | 2021.09.18 |